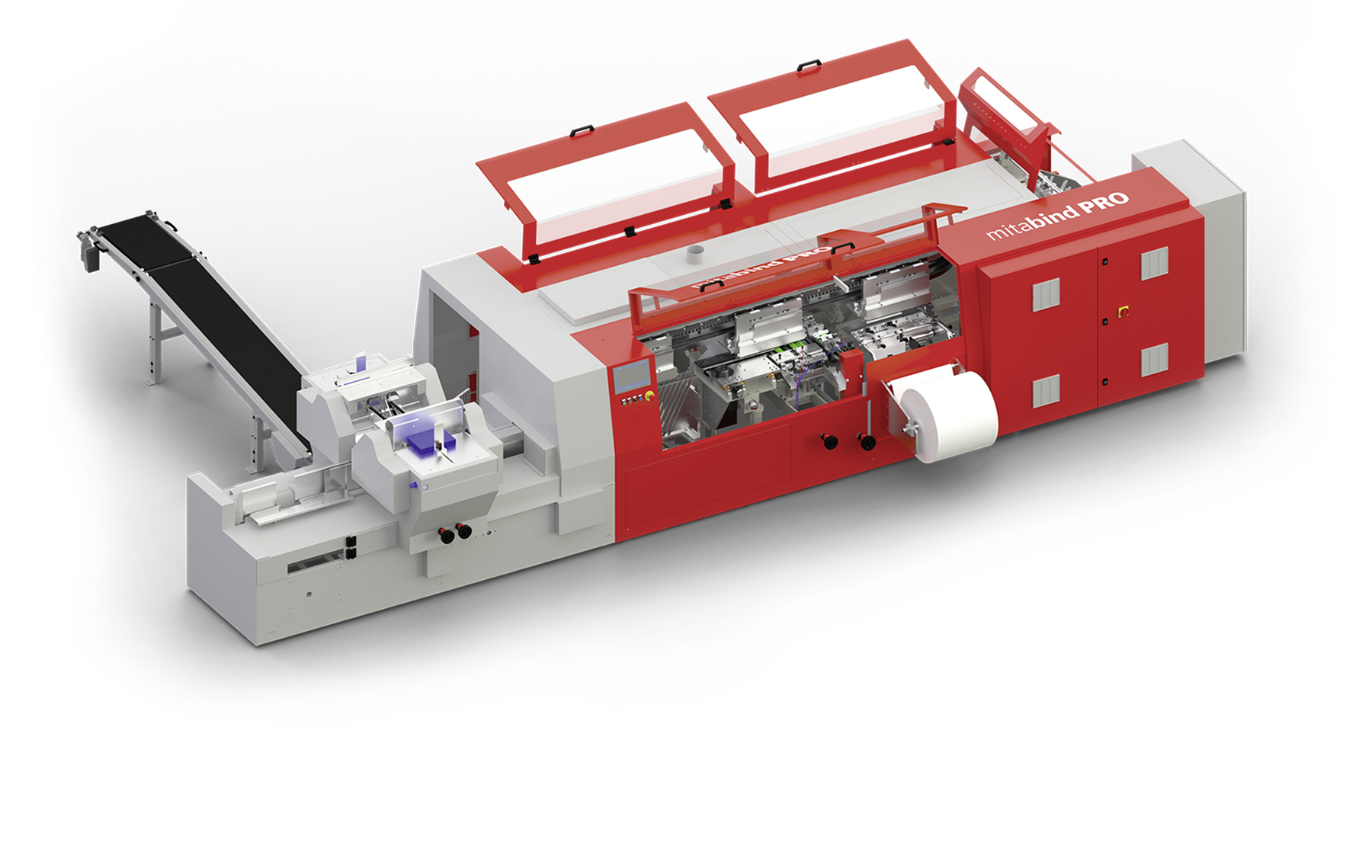

7-clamp perfect binder

mitabind PRO- A short run binder and book block preparation line

The mitabind PRO is a fully automatic 7-clamp perfect binder designed especially for the production of high-quality hardcover book blocks and softcover books in short to medium-runs. Thanks to the integration of an end-sheet feeder and backlining station, yet with a high degree of automation simple format setup times, ease of operation and comparably low complexity and space requirements, it achieves a unique position, particularly in the hardcover book-on-demand sector in the medium speed range (up to 1’800 blocks/h).

Production speed

up to 30 books/min* softcover production

up to 25 blocks/min* block production w. backlining

Clamps number

7

Block formats (width x height x thickness)

min. 100 mm x 150 mm x 3 mm

max. 320 mm x 440 mm x 60 mm

Paper grammage

min. 60 g/m²

max. 170 g/m²

Cover formats (width x height)

min. 205 mm x 150 mm

max. 700 mm x 440 mm

Cover grammage

min. 100 g/m²

max. 300 g/m²

Cover feeder pile height

max. 50 mm

Creasing

double or quadruple

Spine preparation (milling depth)

min. 0 mm

max. 4 mm

Electrics

63 A, 400 V, 3 PNE, 50 Hz

Air consumption

1'200 Nl/min. (6 bar)

Floor space (standard)

approx. 2,60 m x 6,00 m

Weight

approx. 5'000 kg

*The effective performance depends on format, milling depth and pressing time.